How Does An Upflush Toilet Work And Troubleshooting

The upflush toilet working principle is clear-cut and can be fitted in the basement, or any area where introducing a standard bathroom wouldn’t be feasible. Moreover, the edge of installing this system is you don’t have to pay a hefty sum like traditional plumbing—such an unproblematic installation without damaging the floor. The main components of this innovative system include a bowl, pump, water tank, discharge pipe, and check valve. The macerating pump is the system core that pumps the grinding waste upwardly to a higher effluent level. However, similar to other regular ceramic toilets, some problems may happen during use the upflush toilet system. The most common issues are foul odor, leaks, and failure. Let’s grasp how the macerator pump works, begin the macerating process, and how to troubleshoot several typical issues.

Key Working Components Of An Upflush Toilet

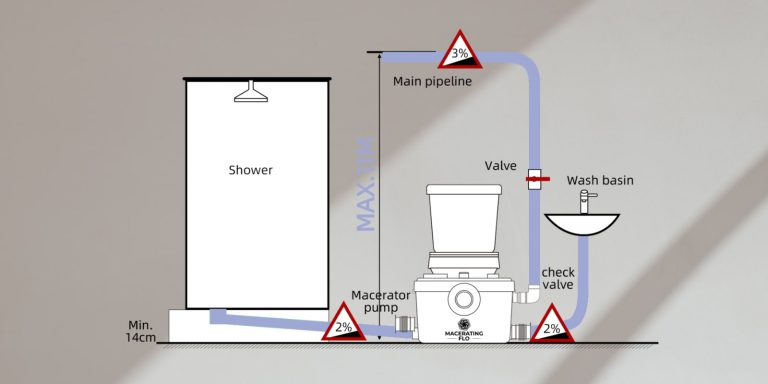

The upflush toilet is also known as a macerating or pump-assisted system. It generally doesn’t depend on gravity like other traditional toilets. As a unique toilet pump system conveying the waste out of your bathroom upwardly by merely grinding and pumping via fine pipes, its essential components include the following:

Toilet bowl and water tank. These two components are like a standard gravity-fed toilet. The bowl retains the waste unless it’s flushed away. Also, several upflush toilets include 2 flushing options on the water tank – pressing the button or pulling the lever.

Macerator pump. It is the heart of the upflush system. Powered by an efficient electric motor, the pump can grind the waste into slurry before transporting them to discharge or waste pipe.

Discharge pipe. The discharge or waste pipe usually has a narrow diameter and delivers waste out of the bathroom.

Check valve. It’s a one-way unidirectional valve that evades the waste from backflow into the pump once the waste is pumped out.

Overall, all these parts create an efficient and convenient alternative, which can replace the traditional gravity-fed toilets in a cost-effective way.

The Upflush Toilet Macerating Process

Water flows into the macerator pump inside as you activate flushing. There is a pressure sensor that encompasses the membrane and the microswitch. It does pressure detection as the water level goes up.

The pump starts working as the water reaches the membrane. The motor starts supplying power to the blades, which begin grinding. After grinding, the tiny and minute effluent particles will fall on the bottom of the pump.

The impeller will pick these particles and pump them out via the waste discharge pipe.

When they are being pumped, they will pass through the discharge elbow that is linked with a 3-quarter-inch narrow pipe.

The system also includes a built-in check valve that prevents wastewater from returning to the pump.

Let’s discuss momentarily the upflush toilet macerating process in a few words.

1.Flushing The Toilet: Water And Waste Enter The Macerator Pump

During flushing via the rear spigot fixture, effluent is released through gravity into the macerator toilet pump, which is fixed behind the bathroom fixture.

2.Maceration Of Waste: Grinding And Liquifying Effluent Into Slurry

Upon the rise of the water level, it creates the pressure which lets the pump switch ON by activating the microswitch. In addition, sharp stainless steel blades are powered by the system motor. The pump begins rotating at 3,600 RPM (revolutions per minute) and grinds persistently every single effluent into small particles.

3.Pump The Waste: Transport The Slurry Upwards

All the grinding particles would be transported upward after mixing with water. The microswitch immediately deactivates, and the macerating process ends after reducing the effluent.

4.Dispose Of The Waste Into The Main Drain Line

The effluent and particles are transported to the sanitary drain or septic tank via a 3/4 or 1 inch in diameter discharge pipe. The check-valve of the macerator pump will repress the reduced effluent backflow inside the pump.

Note: Macerator pump system is known for controlling drainage from numberless fixtures. Unquestionably, from the viewpoint of simultaneous discharging, a major priority is always given to toilet flush.

7 Problems May Happen During A Macerating Toilet Works & How To Solve

Leaking Problem

Two types of leaking can happen in the upflush toilet system. The critical point is to figure out the leakage type. One is called internal water tank seal failure, and the second is an external leak of the pump.

Let’s suppose water is continuously seeping to the bowl. That’s the junction where the water tank is linked with the bowl. You can easily guess it’s because of inner water tank seal failure. You need to replace the parts to minimize the chances of internal leakage.

Nonetheless, tightening the connection of different pipes on the pump will help fix the external leakage of the macerating system. It is easy to handle and would require 5 minutes, depending on the number of connections.

The Macerating Toilet System Is Continuously Running

Suppose the upflush toilet system is running non-stop. You can deal with that issue by doing a few things.

- It may happen if the water tank’s button has been pressed and did not back to the original status automatically. Provided that, make sure the flushing button is completely pressed down and see if it can back to the usual position.

- Furthermore, you can check the fill valve by opening the top cover of the water tank. Use the screwdriver or Allen wrench to open the top by turning counter-clockwise.

- Just for a short duration, at the breaker box, you should turn off the power by swinging the breaker. Before reactivating the power ON, keep doing it unless it ceases working.

- If all these practices don’t settle the upflush toilet running problem. Without delay, contact a skilled plumber to avoid further damages that can result in more far-reaching repairs.

Foul Odor

The remarkable feature of macerating toilets is its solution to minimize bad odor problems in the bathroom—the grinding mechanism of solid waste, before flushing it into a slurry. The microbes are hard to thrive on in slurry that is pumped out immediately. That’s to say, the pump avoids the microbes thriving inside one large chunk of solid waste, which minimizes the odor sources. Despite that, you could detect the faint sewage smell at initial use. To solve this problem, you should choose a pump that can be roof vented or placed with activated carbon. In any of these two ways, the odor can be removed to a great extent.

The Water Level In The Bowl Doesn’t Go Down Even After Flushing

First, check if the bowl holds debris clogging the sanitary unit pipes. Before flushing again, clean out the remaining gunk by running the hot water for around 10 minutes. Indeed, during winter, waste pipes might be frozen. Pouring the hot water would let the ice melt and help unclog and reduce the foul odor. Also, remove the greasy substance that can block the waste pipe and trigger the clogging problem.

The Macerator Toilet Is Making A Loud Noise (Gurgling Or Humming)

Suppose you hear the gurgling noises. That’s a sign. There could be something wrong with your macerator pump. The prevailing cause is small rocks or debris that may come across within the trap way. Water flowing through the sanitary conduit and into the tank may create a gurgling vibration. Here are other possible reasons, namely inappropriate plumbing connection on whether the terminal point of the flushing system into or exiting the tank. In addition, loose bolts or lack of adequate water pressure replenishes the reservoir. However, you must disconnect power for 10 minutes to each electrical component linked to flushing the toilet. Initially, evacuate any obstructions. Now wash the macerating unit and ensure no air is left inward before turning the power on.

Macerating Toilet Takes A Longer Timer To Refill Water

The pump may be applied to handle more effluent that your expectation. If you utilize the macerator pump for food scrapes, it will need a longer time for refiling after flushing. Add some water to the toilet from your bathtub or sink in that situation. It will wash out every tiny leftover bit and help the water trap seal back to the original level.

Why Is The Macerator Pump Not Pumping Properly?

Here you can chew over the macerating toilet system problem and learn how to fix it. Suppose you find that the pump is not properly pumping. Read the steps below to discover the problem and when to call a plumber.

- First, double-check whether the pump receives power smoothly and is plugged in.

- Secondly, evaluate outlet and inlet pipes that whether they are blocked or correctly installed.

- In Lastly, closely monitor the float switch to see whether it’s fixed in the “ON” position.

You may contact the plumber if none of the above solutions resolve the problem.